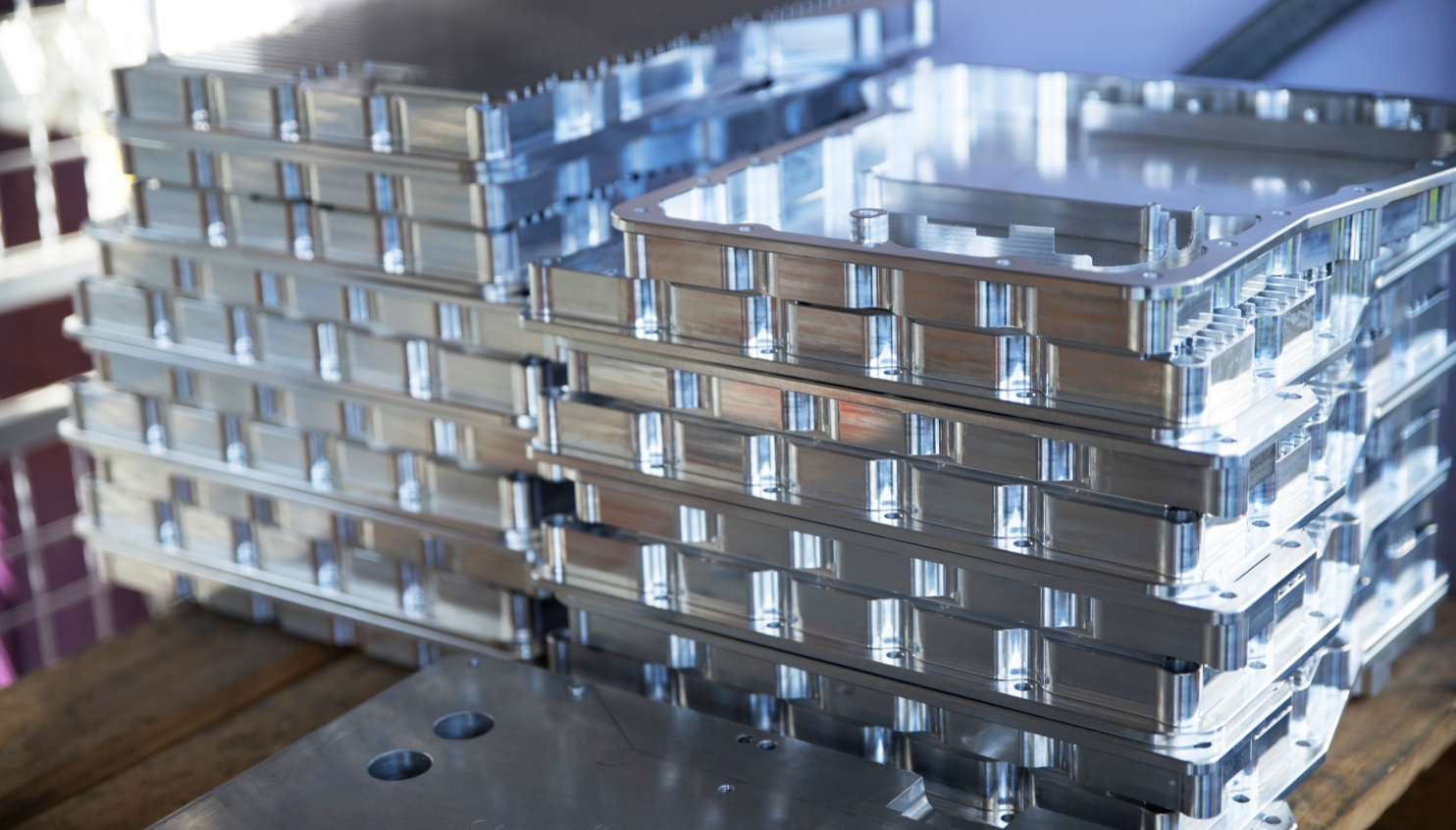

CNC Machining

Precision Without Compromise.

At WGD, CNC machining isn’t just about cutting metal – it’s about delivering the accuracy, repeatability, and turnaround times your business demands.

Capabilities

CNC turning, mill-turn, and 3, 4, and 5-axis milling up to 600mm. Additional services include wire cutting, linear and cylindrical grinding.

Batch Flexibility

Whether it’s one-off prototypes, short runs, or full production, you get the same care and precision without low-volume pricing penalties.

Materials

We routinely work with a variety of steels, aluminum, brass, stainless, plastics, plus customer-supplied castings and forgings.

Finishing Operations

We fully finish parts so they are ready for your assembly, including heat treatment, nitriding, anodizing, plating, oxidizing, surface grinding, and laser engraving.

We have over 20 state of the art CNC machines on-site, supported by GibbsCAM programming which keeps toolpaths optimized, cycle times short, and tolerances always on point. We inspect all components with state-of-the-art measuring equipment from Renishaw and Mitutoyo as well as our fully automated CNC CMM.

Made Right. Delivered Fast. Every Time.

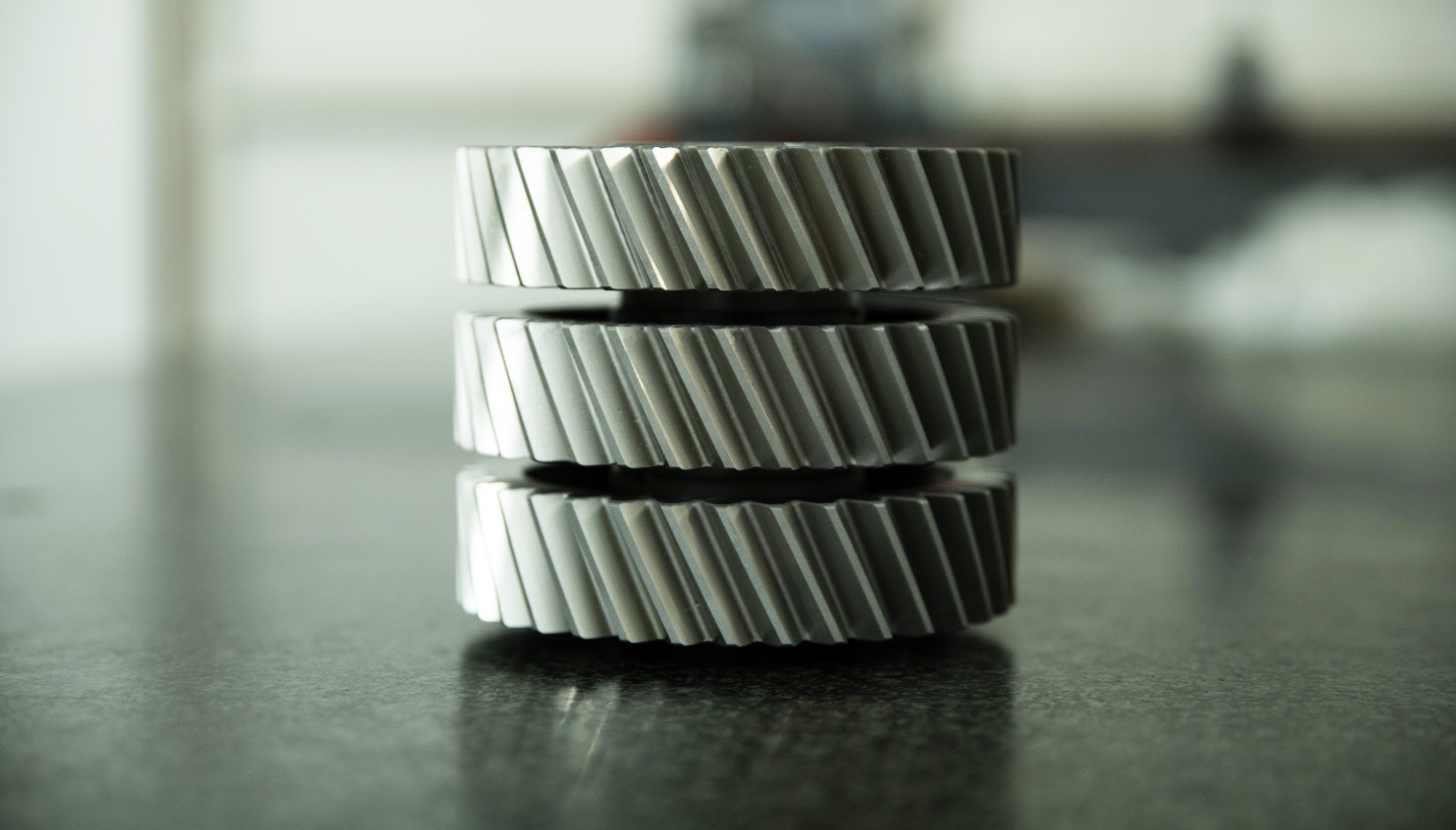

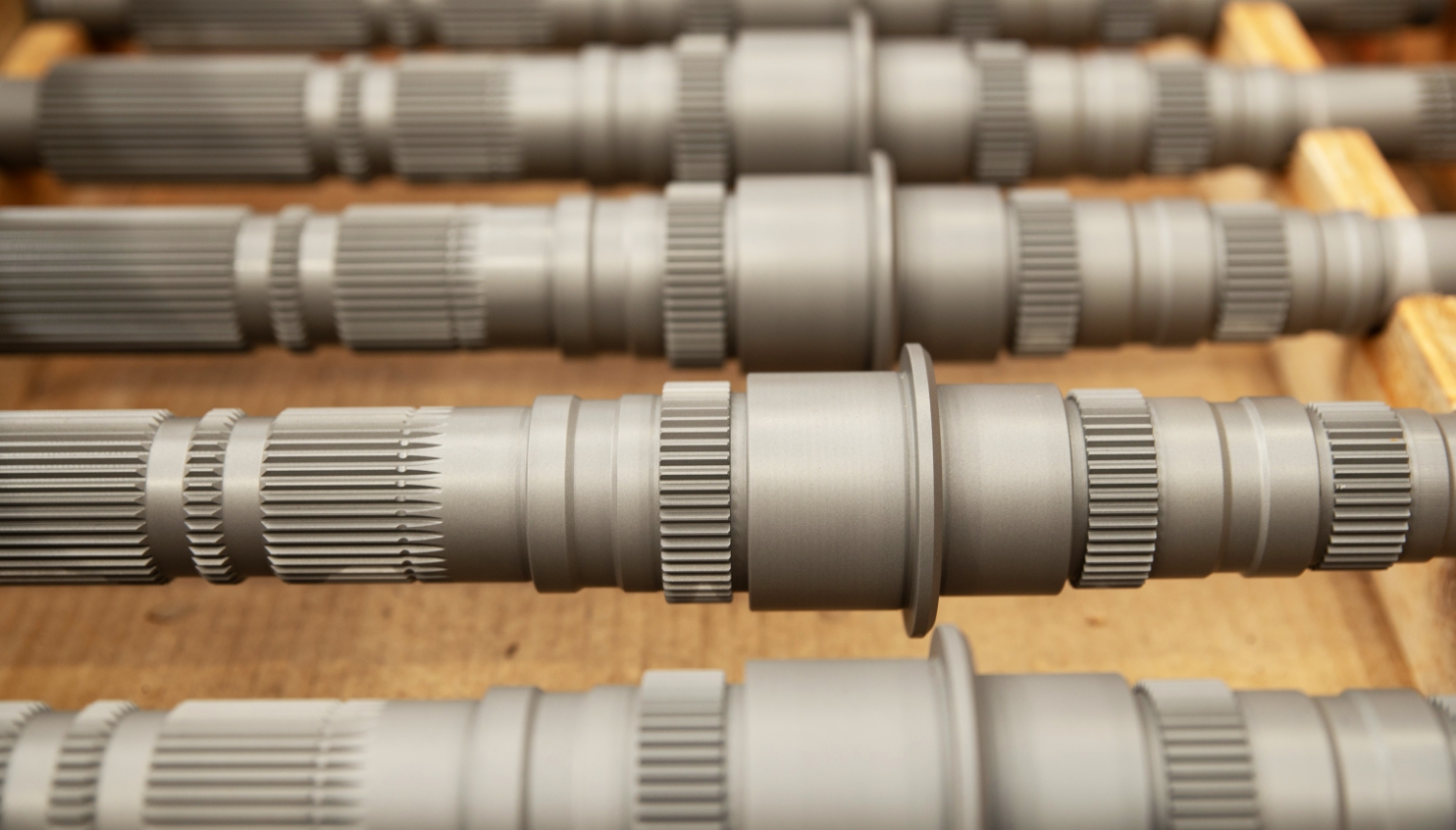

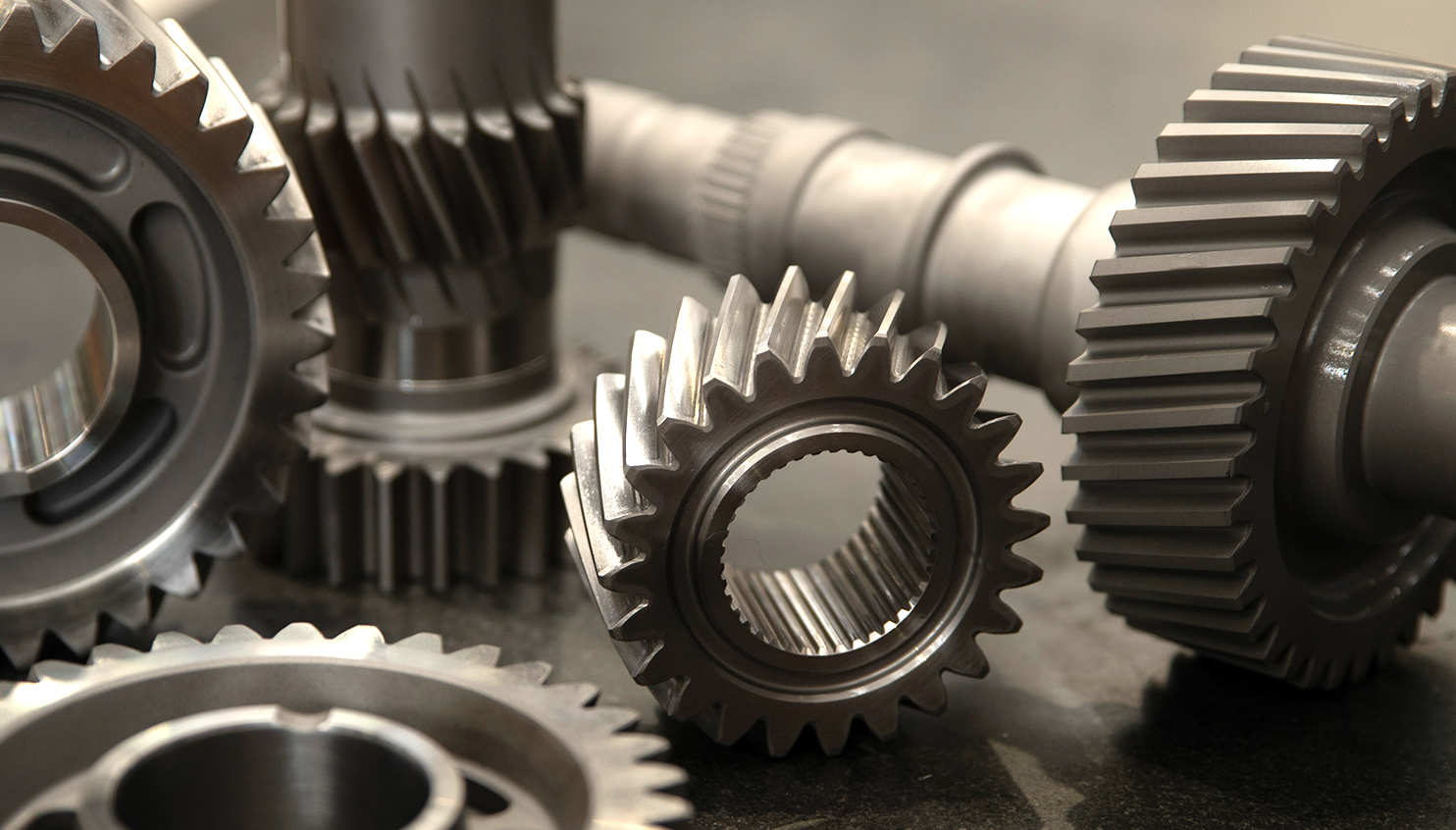

Gears & Shafts

From Blank to Precision Gear. All In-House.

WGD has earned global trust for producing gears that perform under extreme conditions – from aerospace to motorsport.

Hobbing & Shaping

Hobbing up to 300mm diameter and splining of all shapes for precision fitment.

Finishing

Grinding and final machining deliver micron-level precision.

Quality Assured

Every tooth profile is validated using our CMM inspection lab.

Full Records

Full records kept to ISO 9001 standards for material traceability and heat treatment validation.

When failure is not an option, WGD gears deliver the strength and precision you need.

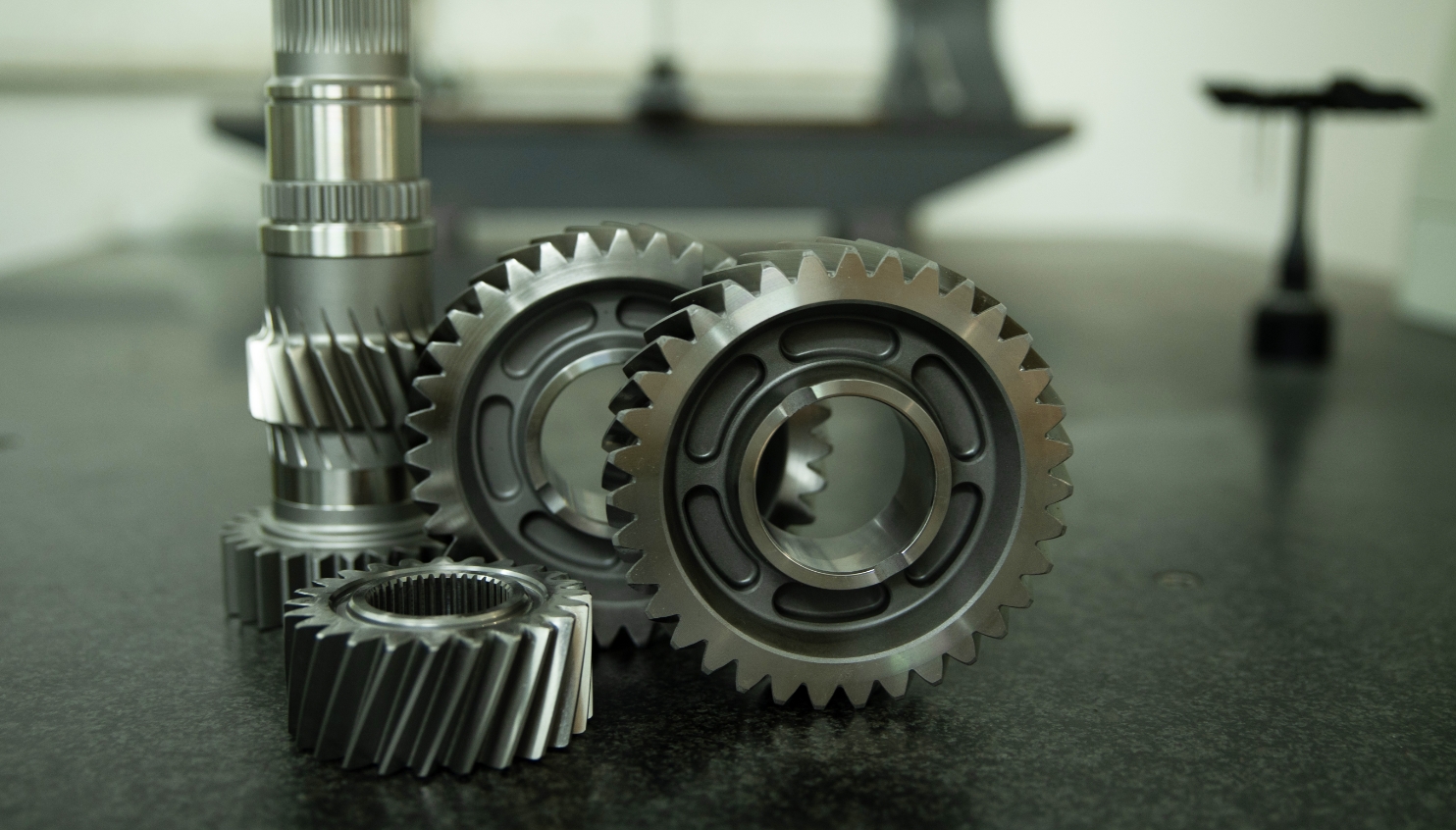

Gearsets

Performance in Every Rotation.

A gearset is only as strong as its weakest component. At WGD, we engineer complete gearsets designed for your requirements and the most demanding applications.

Custom Gearset

From high-performance automotive to industrial applications, and from gear pairs to multi-shaft, lay shaft, and multi-gear arrangements.

Proven Reliability

Our gearsets are trusted by record-holding race teams and corporate manufacturers alike.

Complex Assemblies

Direct drive gears press-fit, keyed, or splined and engagement-type gears with synchros or dogs.

Fast Turnaround

In-house machining and streamlined inspection mean you get your gearsets faster, without compromising quality.

Complex gearsets designed and manufactured to your requirements.

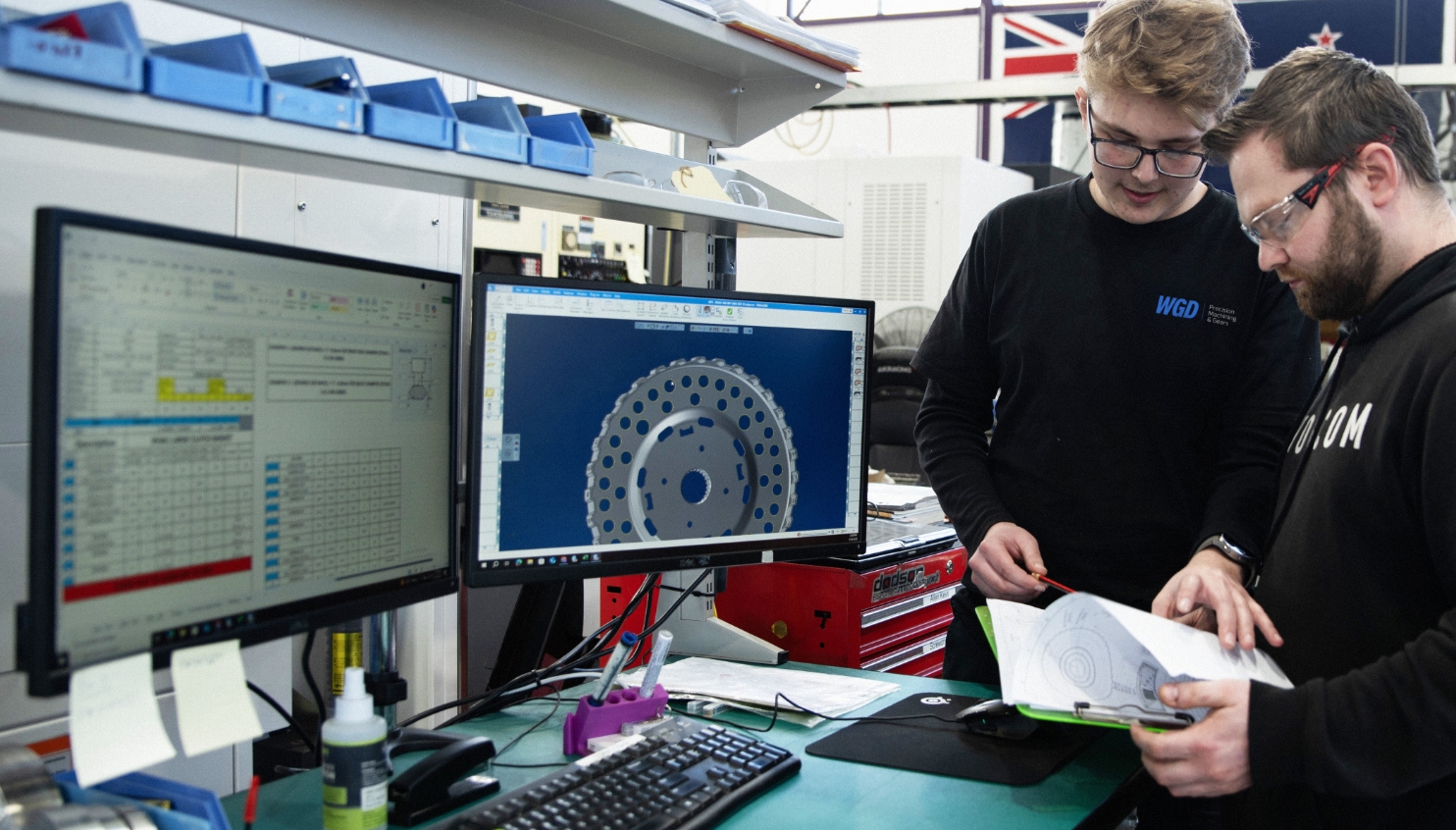

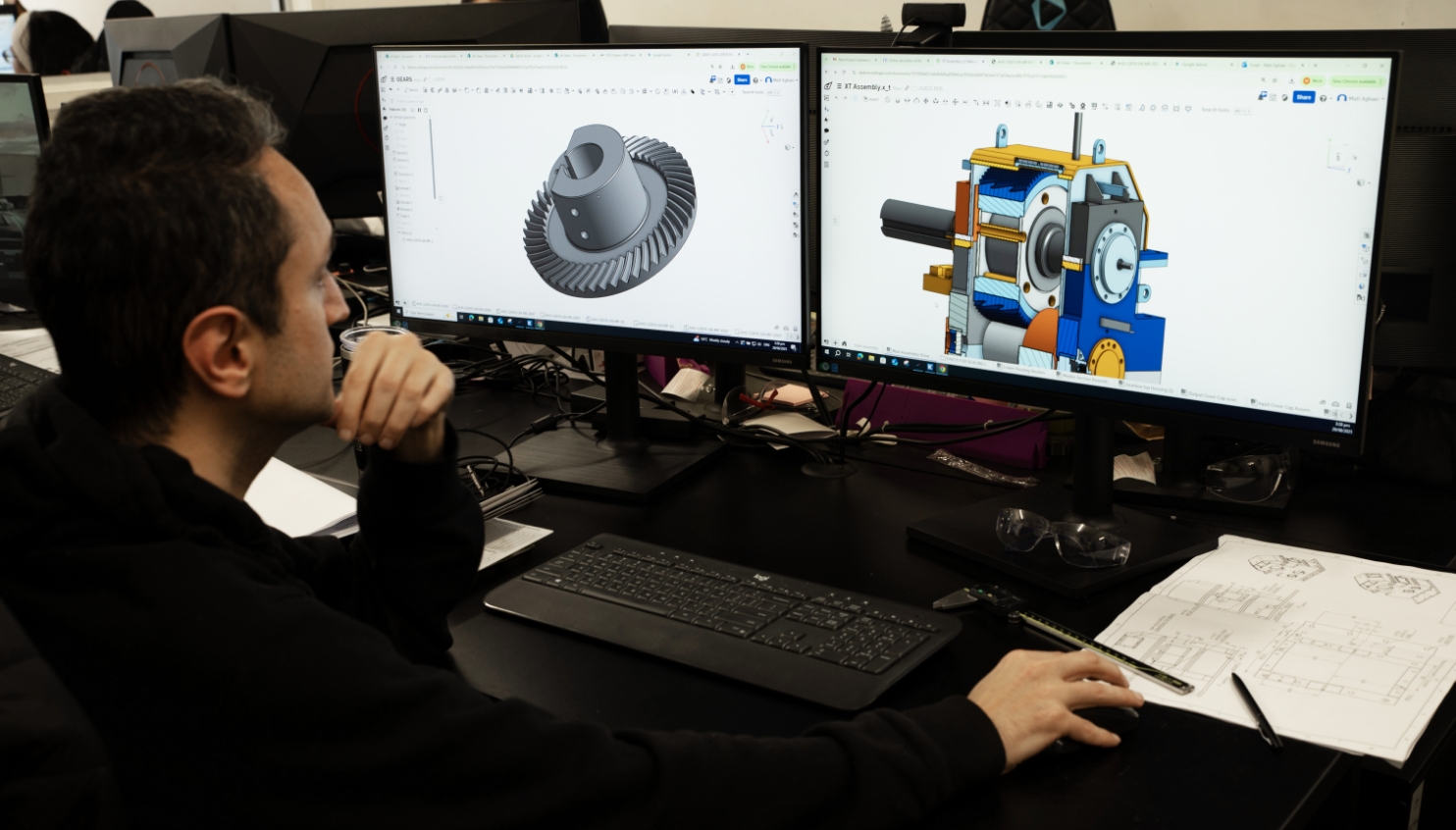

Design & Reverse Engineering

From Concept to Production – Or Back Again.

Not every design is production-ready. That’s where we come in.

Design Optimization

Our engineers collaborate with you to refine designs, cut costs, and improve manufacturability.

Reverse Engineering

Have a legacy component? We can analyze, re-create, and enhance it using the latest technology.

Prototyping

Test your design quickly and cost-effectively before committing to a production run.

Full Project Management

We manage every stage — design, machining, inspection, finishing — so you don’t have to juggle multiple suppliers.